Go to the bench stone, use your two hands and achieve the fundamental knowledge, experience and wisdom in your heart and mind. -Toshio Odate

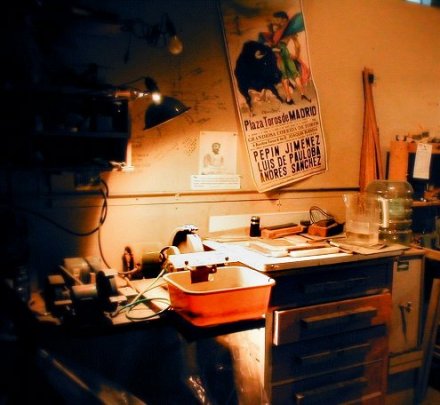

The sharpening area in my studio.

Sharpening high carbon steel is basic to working wood.

Years ago I use to take all of my saw blades, jointer and planer knives and shaper cutters to a man who ran a small sharpening shop just west of downtown. Besides sharpening tools he also sold machinery, power tools, planer and jointer knives and saw blades. He had been connected with woodworking for many years and knew a lot about the trade, the tools, the people and the shops in Milwaukee. I wish I could remember his name. We always called him the guy out on State Street. His shop was actually a block north of State Street, but there wasn’t much else out that way back then so you could always find him if you drove just west of 12th Street on State.

There was a time when most large companies had woodworking shops as part of their organization. I was in one once, as it’s tools were being sold off, that had been on the top floor of a very large department store in the heart of downtown.

When I bought my table saw at an auction the guy on State Street knew that very saw. He asked me if there was still a stain on it from the time such and such had cut a couple of fingers off. The stain is still there, a reminder of the relationship between consequences and inattention.

I bought my shaper from the State Street guy. I discussed it with him for some time working out what I needed and what I could afford. He then ordered it from the manufacturer, set it up in his shop to make sure it worked, made a few adjustments, took it apart again and then delivered it and set it up again in my shop. He showed me a few of the more obscure aspects of that machine even throwing in an extra spindle at no charge. He was generous, but it was also good business. He knew that I was likely to buy more shaper cutters from him if I had two different size spindles.

He sharpened my blades and knives for me but I sharpened my own chisels. Wood chisels have to be kept very sharp at all times or they can be a dangerous tool. If the blade doesn’t do what you are intending it will likely slip. A slip with even a dull blade can cut through skin, tendons and muscle.

There is much said about how to sharpen tools. Just about any discussion among folks who rely on tools tends to get very esoteric about every detail in sharpening. Some folks swear that certain oils used to lubricate the sharpening stone are critical to a “truly sharp edge”. Others insist on particular stones mined from a particular region in Arkansas are absolutely essential to obtaining the “truly sharp edge”. Angles of bevels and micro bevels are studied and discussed. Some sharpening stones are best lubricated with oil, some with water. Water stones need special treatments.

I would walk into the State Street guy’s shop and bring up some of these cabalistic axioms, maybe hoping for some sage advice to set me on the path to the “truly sharp edge”. He took pity on me at some point eventually taking me back into the shop where his one employee was finishing up a set of jointer knives for me.

I don’t know what the guy on State Street would’ve thought of Toshio Odate’s words about sharpening. He died of prostate cancer some years ago. His wife tried to keep the shop open for a while, but what that shop offered was him and he was gone. The many wood shops around the city were gone as well. The neighborhood had gotten rough. One day I found a sign on the shop that it had closed.

What I did learn from the guy on State Street was that there really is no one path to the “truly sharp edge”. He showed me that he used water to lubricate an “oil stone”. That the grit of the stone was what he paid attention to, not where the stone had been mined or manufactured. He showed me that it was how you held your body, when you stroked the blade over the stone, that held the blade at the right angle. In a way he showed me that it was my steel, my stone and my wood that counted.

My set up works for me. I can stand comfortably holding the blade to the stone. I can lean as one with the blade, my hand, my arm, my back moving across a stone that I’ve had for at least 20 years. Water is at hand for lubrication.

I get my knives and blades sharp enough to easily shave a few of my hairs off the back of my wrists. That’s sharp enough. I know how sharp they are so I know how they will work the wood. I feel the cutting and know when to sharpen again. It takes time when I use my two hands. A very deep, very long time.